Single-Fluid Forward

A complete SFF hydraulic system is divided into five functional regions:

Shared, Multi-volume Hydraulic Reservoir- common return filter Transmission Circuit- transmission Cooling Circuit - primary oil/water heat exchanger |

Main Pump Circuit- main pump compensator Steering Circuit- primary steering |

Reservoir

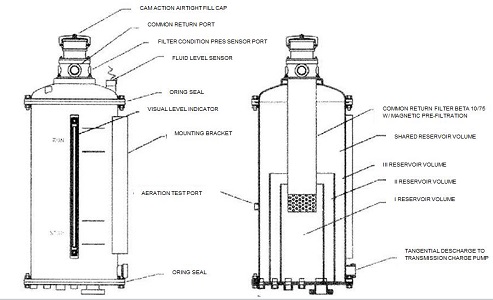

The Single-Forward-Forward hydraulic system distributes fluid from a central compartmented reservoir. The USMC LVSR TD tri-reservoir containing three internal compartments is shown below. The reservoir volume, shape, internal volume geometry and porting is specific to the vehicle application.

Each reservoir compartment is open to the common fluid volume yet retains a dedicated fluid reserve. Reservoir priority is cascaded from the central compartment outward. Control critical and failsafe volumes such as secondary steering draw from the centermost volume. Control critical functions such as primary steering draw from the second volume and other systems from the outer reservoir compartment. In event of fluid loss the centermost volume is first to receive any fluid returning to the reservoir, the second compartment once the first compartment is satisfied and then the third. A fluid loss from systems serviced from the 3rd (outermost) compartment has no effect on systems drawing from the 1st and 2nd levels. Fluid loss from the 2nd and 3rd levels has no effect on the systems fed from the center compartment. SFF affords the ability to survive hydraulic system losses while protecting those critical to vehicle survivability and safety.

All fluid entering the reservoir passes through a common replaceable 10 micron (absolute) BETA 10/75 filter (IAW ISO 17/14) with magnetic pre-filtration and a dearation screen. In addition any top-off oil added to the reservoir must also pass through this filter insuring freedom from top-off oil contamination. The central filter operates from inside to out – captured particles are removed when the filter is replaced. A mechanical-visual and electronic filter condition monitor alert the operator when 30% filter life remains. There are no dipsticks or readily open-able unfiltered ports to limit opportunities for contamination.

Specific reservoir dearation provisions reduce oil-entrained air. In conventionally lubricated transmissions aeration levels reach 5 to 10% by volume. The SFF reservoir demonstrated (USMC LVSR TD evaluation at NATC) oil aeration less than 2% with mineral base OE and less than 1% fluid aeration using synthetic base engine oils.

The SFF reservoir utilizes a mechanical-visual and electronic capacitance fluid level sensor to give the operator an instantaneous vehicle fluid readiness check with or without electrical power. The USMC LVSR time requirement for checking fluids other than axles without electrical power is 15 seconds using the SFF system (Ref: USMC M67854-03-R-5121 PM- MT-PRF-01).

Connect with us

Contact us today for more information

Office: 715-536-8600

Cell: 920-540-6086